The history of matcha

Matcha is a powdered green tea made from whole tea leaves. It has been used in traditional Japanese tea ceremonies for centuries and has become popular in recent years as a healthful alternative to other drinks.

Making matcha is a centuries-old tradition that is still followed today.

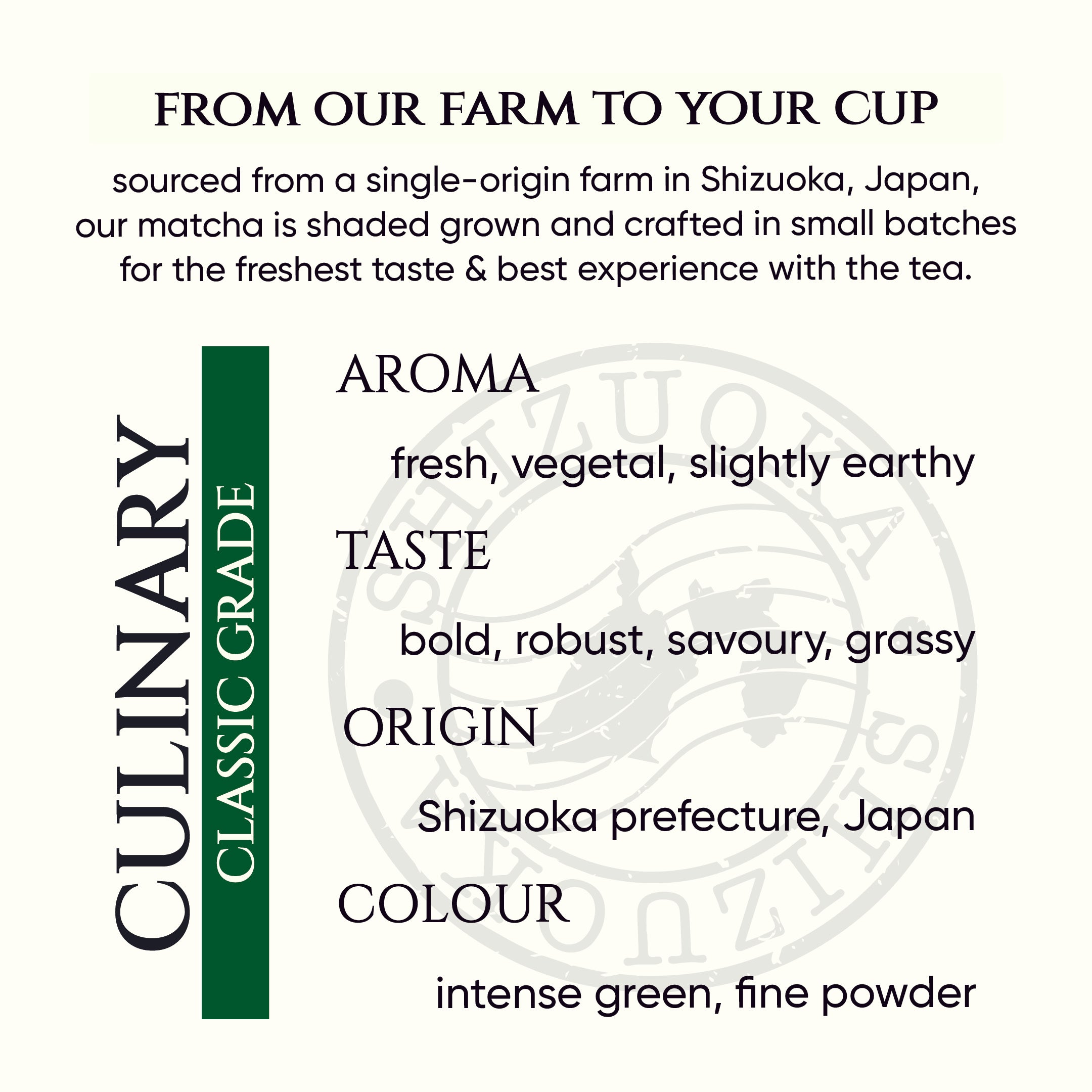

Matcha is made from the leaves of the Camellia sinensis plant, which are shade-grown for about three weeks before harvest.

Manufacturing Process of Matcha

To process tea leaves into matcha, they are first harvested.

Once harvested, the tea leaves are washed before steaming them.

The steaming process helps the tea leaves retain their green colour and amino acids. It also prevents the tea leaves from oxidising.

The tea leaves are flash steamed at 100 degree celsius for 30-40 seconds.

After this, they are cooled using strong winds, which also removes excess water from the leaves.

Once the cooling process is over, the leaves are transferred to a large oven to be dried completely.

The oven has a conveyor belt inside moving at different speeds at each stage.

Drying process aims to minimise the moisture level in the tea leaves so they can be stored for a longer time.

The drying process takes about 20 minutes.

Once the above process is done, the dried leaves are passed through another machine that sort the leaves and stems and further dries the leaves.

The stems are waste products in this case and the process is repeated a few times to make sure all the leaves are without stalk.

At this point, the leaves have a 5% of moisture content and are called Aracha, which means “raw tea” and is also called crude tea.

Aracha needs to be further refined. The raw tea goes through rounds of sifting to further remove any small stems.

Then the leaves are cut smaller. The Aracha has turned into Tencha.

Tencha is stored in cool rooms until it has to be processed into Matcha. This ensures the matcha is fresh when it reaches its end consumer.

While Tencha can be processed manually, it is highly labour intensive.

For this reason, the cultivators have adopted machine powered production of matcha.

The tencha leaves are ground in machine stone mills.

While working with the machine, the producers still have to proceed with caution. If the machine works very fast, it could generate heat and damage the nutrient profile of matcha.

The machines have to maintain a certain pace for the end result to be a bright green colour matcha with a smooth texture.

At the end of these series of processes, a very fine, vibrant green powder is achieved. Matcha production is a painstaking process, but the results are a deliciously rich and healthy drink.

Here's Why You Need To Include Matcha In Your Routine

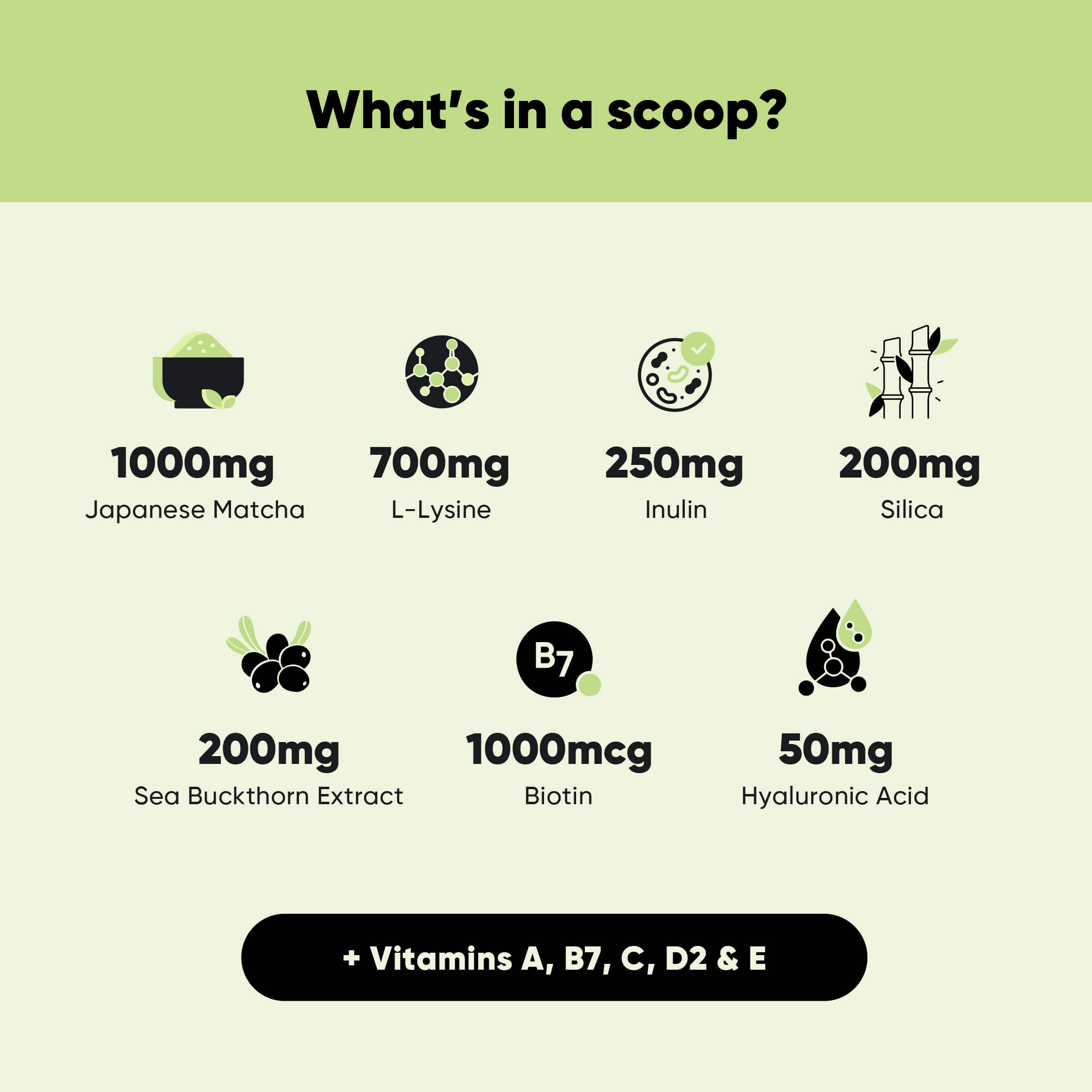

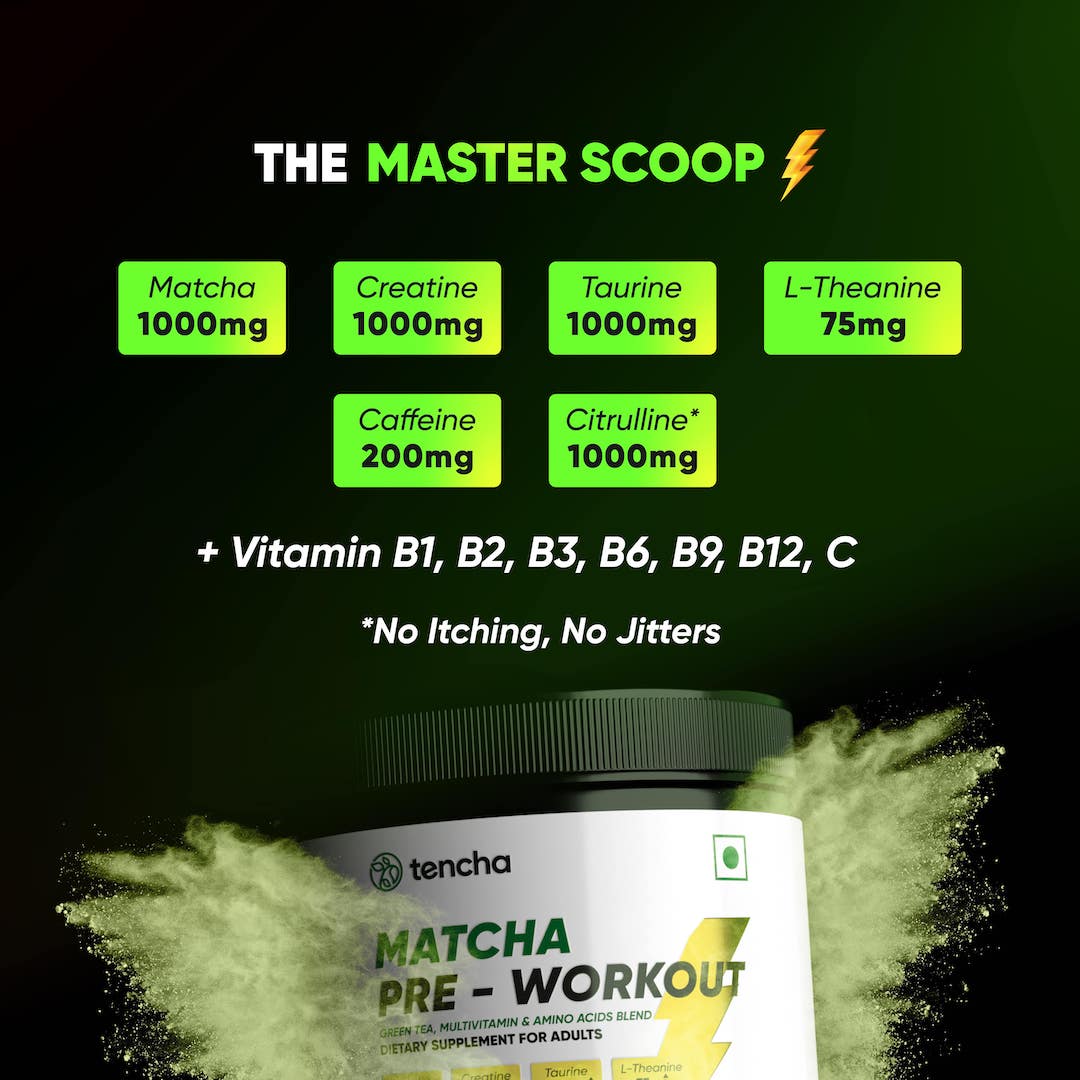

Matcha has a high chlorophyll content, and is distinct umami flavour. When we consume matcha, we are consuming the whole tea leaf and deriving all the antioxidants and nutrients the plant offers. Matcha also contains L-Theanine, an amino acid that can promote relaxation without causing drowsiness.